Exploring the importance of Aluminum Castings in today’s manufacturing

Wiki Article

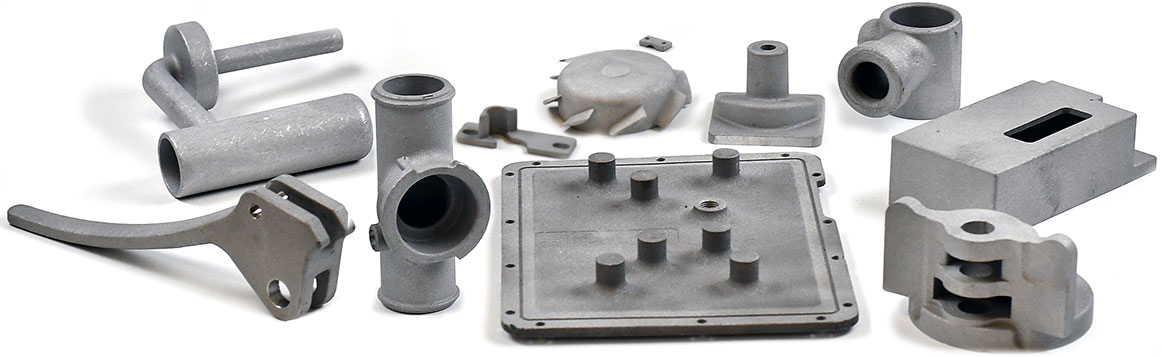

Discovering the Conveniences and Practical Use Aluminum Castings in Today's Market

Aluminum spreadings have come to be increasingly pertinent in various industries as a result of their distinct features. Their lightweight nature and resistance to corrosion make them ideal for demanding applications. In addition, the exceptional strength-to-weight proportion offers substantial advantages in layout and production. As industries remain to explore their capacity, the full scope of aluminum spreadings' advantages and applications remains to be fully discovered. What exists ahead for this functional material?The Lightweight Advantage of Light Weight Aluminum Castings

Lots of products are made use of in production, aluminum spreadings stand out primarily due to their lightweight buildings. This characteristic makes aluminum castings an eye-catching choice for numerous sectors, particularly in aerospace and automotive applications, where weight reduction is vital for boosting fuel efficiency and performance. The lightweight nature of aluminum enables makers to develop parts that are less complicated to set up and manage, eventually minimizing labor expenses.Additionally, the capacity to generate complicated forms without considerable weight charges allows developers to innovate while maintaining structural honesty. Aluminum castings can effectively change much heavier products, causing substantial savings in delivery and functional costs. Their light-weight advantage additionally adds to improved product long life, as lighter parts often bring about minimized deterioration on machinery. On the whole, the light-weight buildings of light weight aluminum castings give producers with an one-upmanship, cultivating developments in item style and efficiency across different sectors.

Phenomenal Deterioration Resistance

Light weight aluminum castings possess an all-natural resistance to oxidation, which considerably improves their longevity in numerous settings. This intrinsic building not only contributes to their durability yet additionally lines up with the light-weight benefit that aluminum supplies. As an outcome, aluminum spreadings are progressively recognized for their phenomenal rust resistance in countless applications.

Normally Immune to Oxidation

Among the standout attributes of aluminum castings is their outstanding deterioration resistance, which stems from an all-natural oxidation process. When exposed to air, aluminum responds to create a slim, safety layer of light weight aluminum oxide. This layer serves as an obstacle against further oxidation and protects the underlying steel from destructive elements such as dampness and salts. Unlike other metals, this oxide layer is self-repairing; if harmed, it rapidly reforms when revealed to air. This special home enhances the longevity of light weight aluminum castings in different environments, making them excellent for applications in industries such as aerospace, automotive, and marine. The natural resistance to oxidation greatly minimizes upkeep costs and raises the dependability of light weight aluminum castings in requiring problems.Lightweight Longevity Advantage

The light-weight nature of aluminum castings contributes substantially to their durability, making them a useful choice in different markets. This exceptional sturdiness is largely credited to light weight aluminum's natural resistance to deterioration, which is enhanced additionally through anodizing and other surface therapies. Unlike several steels, light weight aluminum does not rust; instead, it develops a safety oxide layer that guards it from ecological damage. This property is particularly beneficial in industries such as automobile and aerospace, where weight reduction is critical without jeopardizing toughness. In addition, the long life of aluminum castings decreases maintenance costs and substitutes, offering financial advantages in time. Their lightweight resilience and rust resistance setting aluminum castings as a premium material for modern manufacturing applications.

Superior Strength-to-Weight Proportion

A remarkable quality of aluminum castings is their exceptional strength-to-weight ratio, that makes them very preferable in numerous applications. This inherent property allows aluminum castings to endure considerable tension while staying lightweight, a critical aspect in sectors such as aerospace, vehicle, and production. Engineers typically choose light weight aluminum castings for components that require both resilience and reduced weight, boosting gas performance and efficiency.The high strength-to-weight ratio also facilitates the layout of detailed forms and frameworks, making aluminum castings functional for complicated applications. The capability to keep structural integrity under tough problems guarantees durability and dependability in products, from airplane frameworks to auto components. This advantage adds to the growing fad of using light weight aluminum castings in cutting-edge designs, inevitably causing improved performance and efficiency throughout varied industries. Subsequently, the exceptional strength-to-weight proportion of aluminum spreadings places them as a pivotal product in modern engineering and production.

Cost-Effectiveness in Manufacturing

Cost-effectiveness in aluminum casting manufacturing is primarily accomplished with decreased product waste and efficient manufacturing procedures. By optimizing layouts and utilizing sophisticated methods, manufacturers can reduce excess material usage while keeping quality standards. This method not just decreases manufacturing costs but likewise adds to extra lasting methods within the sector.Reduced Material Waste

Decreasing material waste in aluminum spreading procedures greatly enhances manufacturing effectiveness. By enhancing the style and production strategies, firms can minimize excess scrap and improve resource application. This decrease in waste not only decreases material costs but also adds to a more sustainable production model. The capacity to reuse light weight aluminum further supports cost-effectiveness, allowing manufacturers to redeem and recycle products without endangering high quality. As the sector significantly concentrates on sustainability, minimized material waste lines up with environmental goals while concurrently boosting success. Eventually, effective use raw materials strengthens the affordable setting of organizations in the marketplace, making light weight aluminum castings a favorable alternative in numerous applications. The strategic technique to lessening waste reflects a dedication to this post both economic and ecological obligation.Reliable Production Processes

While traditional production processes can incur substantial expenses, light weight aluminum casting offers a much more efficient alternative that boosts overall manufacturing success. This approach reduces material waste and enables accurate control over the manufacturing process, bring about decreased labor and functional costs. The capacity to produce complicated forms with fewer actions additionally improves manufacturing, adding to much shorter preparations. Additionally, aluminum's lightweight nature and outstanding thermal conductivity allow for energy savings throughout production and in the final application. By using modern-day spreading innovations, suppliers can achieve greater throughput without giving up quality. Aluminum spreading stands out as a cost-efficient solution, making it an attractive option for services intending to maximize their manufacturing procedures in today's affordable market.Versatility Throughout Industries

Light weight aluminum spreadings show remarkable flexibility across various industries, as they can be tailored to meet specific requirements and applications. In the automobile industry, light weight aluminum spreadings are made use of in engine blocks, transmission real estates, and wheels, supplying light-weight yet sturdy remedies that boost gas performance. The aerospace sector additionally gains from light weight aluminum castings, utilizing them in architectural parts and engine components because of their strength-to-weight ratio.In the consumer products market, makers utilize aluminum spreadings for items ranging from pots and pans to furniture, giving both visual charm and functionality. The electronic devices market uses aluminum spreadings for real estates and warm sinks, making sure effective thermal monitoring. Additionally, the building market investigate this site leverages aluminum castings for structural parts and architectural elements, boosting durability and layout flexibility. This wide applicability highlights aluminum spreadings as a vital resource, fulfilling the diverse needs of different markets while maintaining high efficiency and dependability.

Sustainability and Ecological Impact

As industries increasingly focus on sustainable methods, aluminum castings become a green option as a result of their recyclability and low ecological footprint. Aluminum is just one of the most recycled products worldwide, with the capacity to be repurposed multiple times without deterioration of quality. This particular significantly lowers the demand for resources and power consumption connected with primary light weight aluminum manufacturing, which is energy-intensive.Additionally, aluminum spreadings add to lightweight layouts, leading to fuel effectiveness in transport applications such as automotive and aerospace sectors. Their sturdiness and resistance to deterioration expand item lifespans, even more lessening waste and source use in time. Lots of makers are adopting responsible sourcing and environmentally pleasant manufacturing methods, boosting the sustainability of light weight aluminum casting procedures. Overall, light weight aluminum castings represent a practical option for services intending to minimize their environmental effect while accomplishing efficiency and i loved this performance.

Innovations in Aluminum Spreading Technologies

Current improvements in aluminum spreading modern technologies have significantly improved the efficiency and top quality of production procedures. Advancements such as 3D printing and advanced mold-making techniques have actually allowed manufacturers to develop elaborate designs with minimized material waste. This change not only boosts the precision of actors elements yet likewise shortens preparations, allowing for quick prototyping and faster market entrance.

In addition, the consolidation of advanced computer system simulations aids in forecasting potential issues during casting, bring about higher-quality outcomes (Metal Castings). Making use of lightweight alloys has actually also added to the growth of stronger, much more sturdy products, satisfying industries ranging from vehicle to aerospace

Additionally, automated casting processes have actually arised, reducing human error and raising manufacturing speed. Collectively, these advancements are transforming the aluminum casting landscape, driving better competition and sustainability in production. As industries remain to develop, these innovations will certainly play an essential duty in meeting future needs for efficiency and top quality.

Often Asked Questions

Exactly How Do Light Weight Aluminum Castings Contrast to Various Other Steels in Regards To Thermal Conductivity?

Light weight aluminum spreadings exhibit superior thermal conductivity contrasted to several steels, such as steel and iron - Aluminum Castings. Their light-weight nature and efficient heat distribution make them perfect for applications requiring effective thermal management in numerous sectorsWhat Are the Usual Problems Located in Light Weight Aluminum Castings?

Typical defects in light weight aluminum castings consist of porosity, shrinkage, additions, and surface area abnormalities. These concerns usually emerge from improper cooling prices, poor mold and mildew style, or contaminations, impacting the overall top quality and efficiency of the last product.Can Aluminum Castings Be Recycled, and Just how?

Light weight aluminum castings can be recycled properly. The procedure includes collecting, melting, and changing the light weight aluminum, which reduces waste and conserves sources. This reusing adds to sustainability while maintaining the product's buildings for future use.What Are the Common Lead Times for Light Weight Aluminum Casting Manufacturing?

Usually, lead times for light weight aluminum casting manufacturing array from 2 to six weeks, depending on aspects such as complexity, tooling needs, and production quantity. Effectiveness can improve with well-known vendor relationships and enhanced manufacturing procedures.Exactly how Does the Surface Complete Affect Light Weight Aluminum Spreading Performance?

The surface area coating considerably influences light weight aluminum spreading performance by influencing deterioration resistance, visual high quality, and friction characteristics. A smoother surface boosts longevity and functionality, while a rougher appearance can improve bond for subsequent finishes or therapies.Numerous materials are utilized in manufacturing, light weight aluminum spreadings stand out largely due to their lightweight residential or commercial properties. When subjected to air, light weight aluminum reacts to develop a slim, safety layer of light weight aluminum oxide. Cost-effectiveness in aluminum spreading manufacturing is mainly accomplished via reduced material waste and reliable manufacturing processes. Minimizing product waste in light weight aluminum casting processes considerably boosts production efficiency. Eventually, effective usage of raw products reinforces the affordable position of companies in the market, making aluminum castings a positive alternative in numerous applications.

Report this wiki page